CNC milling is one of the types of material processing to give the material precise shape, size and characteristics. In the past, when working with metal or other materials, a group of skilled craftsmen had to work which, under the watchful eye of the person supervising their work, did all the work by hand. This has changed dynamically with the development of technology, including robotics. Now the programmers and operators monitor the entire machining process.

At first glance, the whole process does not look very complicated

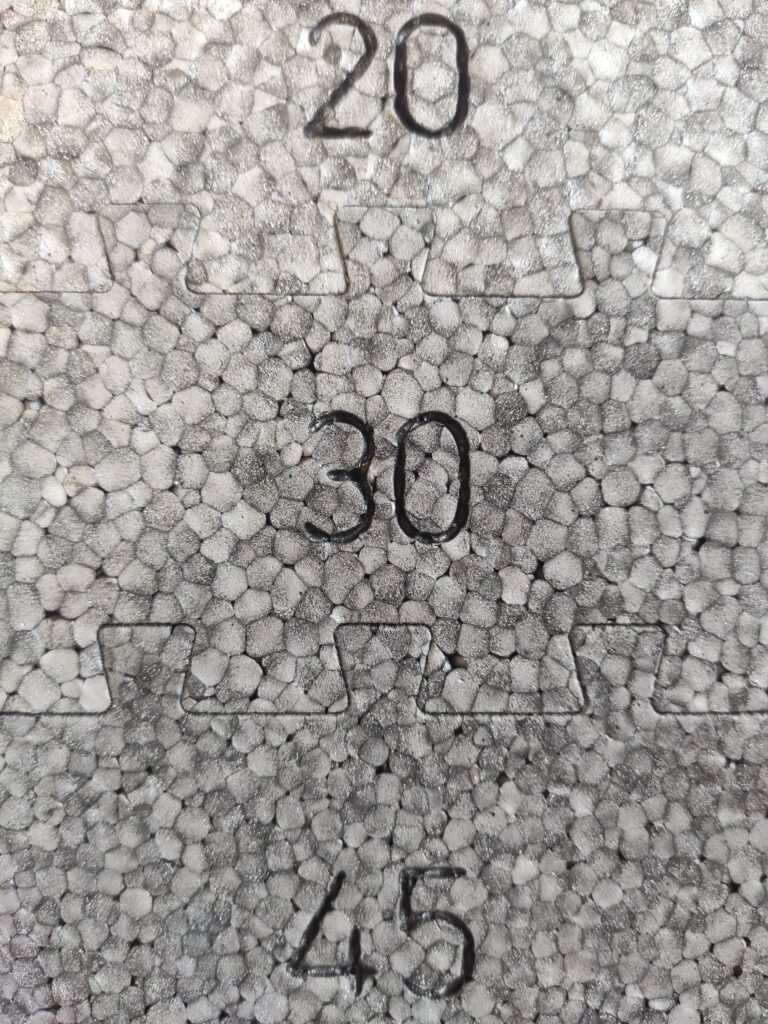

but properly programmed devices offer the ability to perform routers with accuracy, which would not be possible with conventional machine tools. Exactly for this precedure systems are used for precision milling and lathe machining.

CNC technology considerably facilitates and accelerates series production,

why it is used in many industrial production companies – in popular industries such as automotive, electronics, aviation, packaging, but increasingly also in artists. It consists in the introduction of all the settings in the computer program (this is the most time-consuming part of the process), whereby further production steps are carried out fully automatically and repeatably. The application of the CNC method primarily leads to a much faster order execution as well as the agreement of the cutting accuracy with the project assumptions on a very high level.